When an existing process, product, or service is being applied in a new way.When a process, product, or service is being designed or redesigned, after quality function deployment (QFD).Ideally, FMEA begins during the earliest conceptual stages of design and continues throughout the life of the product or service.įailure Modes and Effects Analysis Example When to Use FMEA Later it’s used for control, before and during ongoing operation of the process.

FMEA is used during design to prevent failures. The purpose of the FMEA is to take actions to eliminate or reduce failures, starting with the highest-priority ones.įailure modes and effects analysis also documents current knowledge and actions about the risks of failures, for use in continuous improvement.

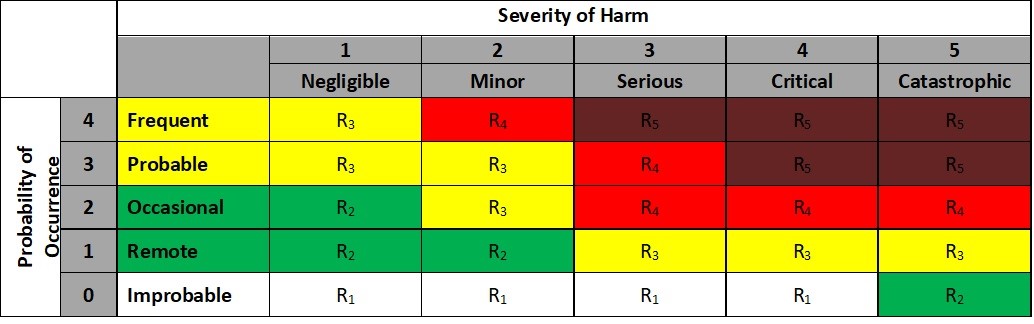

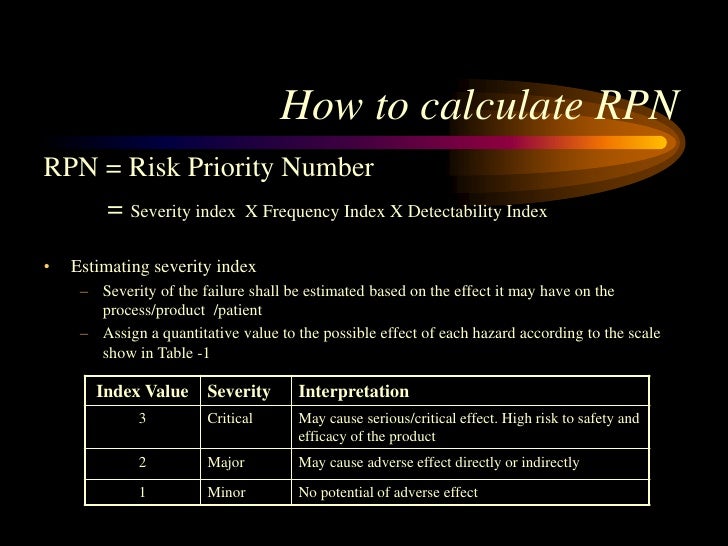

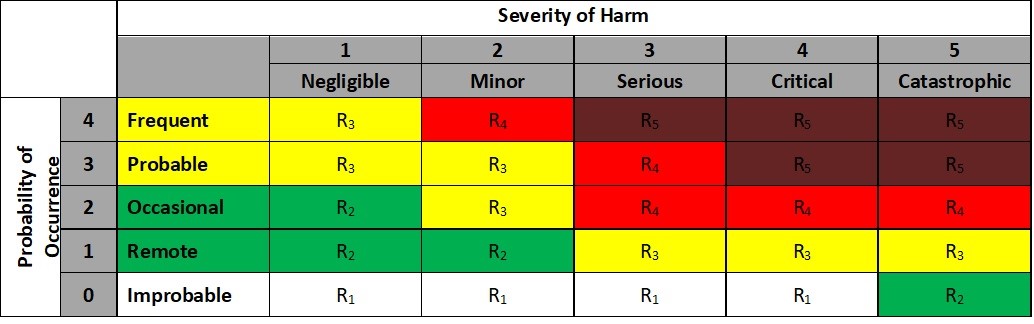

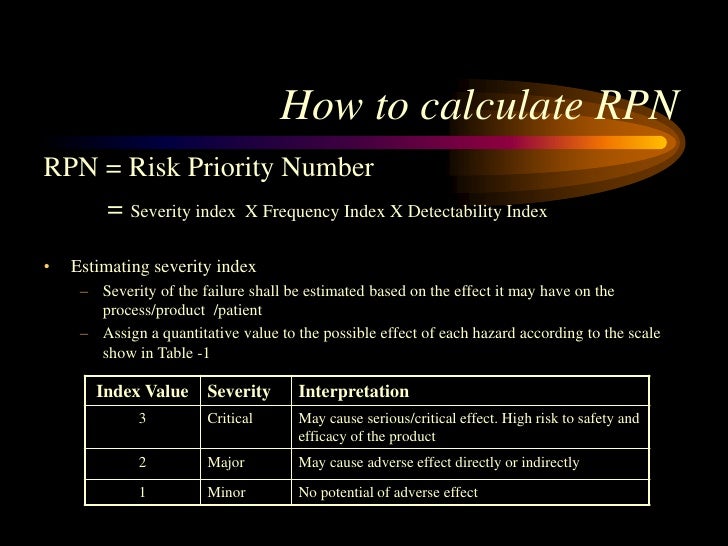

"Effects analysis" refers to studying the consequences of those failures.įailures are prioritized according to how serious their consequences are, how frequently they occur, and how easily they can be detected. Failures are any errors or defects, especially ones that affect the customer, and can be potential or actual. "Failure modes" means the ways, or modes, in which something might fail. military, failure modes and effects analysis (FMEA) is a step-by-step approach for identifying all possible failures in a design, a manufacturing or assembly process, or a product or service. This presentation will compare and contrast the traditional RPN and the action priority (AP) table methods for FMEA as well as provide practical examples of the application of the action priority (AP) table method.Quality Glossary Definition: Failure mode effects analysis (FMEA)Īlso called: potential failure modes and effects analysis failure modes, effects and criticality analysis (FMECA)īegun in the 1940s by the U.S. The priorities are derived from weighted hierarchical rankings considering Severity, Occurrence, and Detection. The AP tables assign one of three suggested rankings (High, Medium, and Low Priority) for each action based upon the Severity, Occurrence, and Detection values. The RPN has been replaced by the action priority (AP) table. One of the major changes with the new AIAG-VDA FMEA process is the traditional RPN has been eliminated. The Automotive Industry Action Group (AIAG) and the Verband der Automobilindustrie (VDA) jointly released an updated FMEA handbook on April 2, 2019. The RPN output of an FMEA is a relative risk score for each failure mode, which is used to rank the failure modes of relative risk to allow the organization to prioritize risk mitigation and reduction activities. Detection (D) is the probability that control (design, inspection, alert/warning) will eliminate, mitigate, or catch the defect. Probability of occurrence (O) is the likelihood that a harm or cause will occur and that it will induce the detrimental consequences of the associated hazard. Severity (S) is a measure of the seriousness of the possible consequences of a hazard. Mark Allen Durivage, Managing Principal Consultant, Quality Systems Compliance LLC, Lambertville, MI, USAįailure mode effect analysis (FMEA) risk priority number (RPN) scores have traditionally been used to quantify risks for use, design, and process FMEAs.įMEA helps quantify and prioritize risk using severity of the harm, probability of occurrence, and probability of detection ratings that are multiplied together to produce the RPN.

0 kommentar(er)

0 kommentar(er)